M-I Rubber Fender

Introduction

Rubber fender is one of the most international advanced wharf (ship) protection equipment developed in modern times, with the characteristics of low reaction force, high energy absorption, corrosion resistance and long service life. It is suitable for use in various climates and working conditions, and has the properties of aging resistance, wear resistance and seawater corrosion resistance, furthermore, it's easy to maintain, and it doesn't cost big investment. As the rubber itself has a high elasticity, so that the fender has a high degree of cushioning, shock absorption and silencing effect. Therefore, rubber fender has become one of the indispensable protective equipment in modern port engineering construction.

1.Product analysis

M-I rubber fender is a new type fender designed for offshore drilling platform on the basis of M rubber fender (a rubber fender with a cross section like the letter M, as shown in Figure 1), with simple structure, easy installation characteristics. Its counter-force and mechanical property all meet the requirements of rubber fender for drilling platform, moreover, its excellent characteristics make it widely used in oilfield development.

.jpg)

Fig. 1 Schematic diagram of M section

Figure 2 is the schematic diagram of M-I rubber fender, which is made of natural synthetic rubber +Q235A. The natural synthetic rubber has good aging resistance, oil resistance and sea water corrosion resistance, and high wear resistance, so the good material ensures the mechanical properties and product quality of M-I fender. The surface roughness is Ra3.2μm, Fender surfaces shall be free of cracks and be without surface scar and starved area that may affect service performance.

Fig. 2 Schematic diagram of type M-I

2.Mechanical property

2.1.The physical and mechanical properties of M-I fender material are shown in Table 1.

Table 1. The physical and mechanical properties of material

| Item | Index | Actual Specs |

| Tensile stength MPa | ≥16 | 17.2 |

| Elongation at break % | ≥300% | 460 |

| compression set(70℃ 22h 25%)% | ≤28 | 22 |

| Shore hardness Shore under the condition of hot air aging | ≤82 | 72 |

| Change rate of tensile strength% | ≤20 | 19 |

| Change rate of breaking strength% | ≤20 | 18 |

| Hardness change() | Maximum allowable increase of8 degrees | 4 |

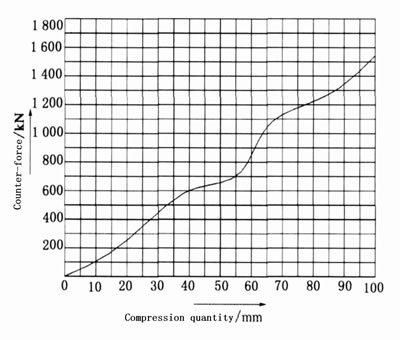

2.2.The performance curve of M-I rubber fender is shown in Figure 3

Figure 3 M-I fender counter-force deformation curve

3.Mould design

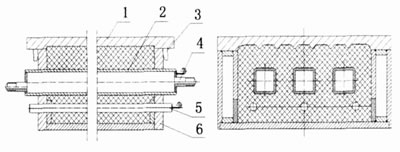

The die structure diagram is shown in figure 4. The mould has 2 parts, upper and middle mold, the fender iron body is the lower die, the die structure is simple, and the loading and unloading mould is convenient.

Figure 4 Mold structure

1. upper die 2. side core 3. location block 4. air inlet piping 5. small core 6. middle mould

The specific structure of the die is analyzed as follows:

i)The upper and lower die are positioned by 4 positioning blocks of the conical pin and the end face, so the positioning is reliable and the use is convenient.

ii)The central mould frame and the 3 square cores pass through the steam, so as to accelerate the vulcanization speed of the rubber compound.

iii)The fender production process is labor-saving and time-saving, first putting rubber material tiled to the mold cavity, then cover the upper die, drag the mold to the vulcanizing machine plate with the crane, Pressurization, steam, keep pressure, and then die out after vulcanizing.

iv)When the die is unloaded, the upper die is lifted first by the crane, and then the square core and the small core are pulled out one by one, then the middle die and fender are dragged to the vulcanizing press, and 2 certain high round tubes (pads) are placed on the fender surface, when the pressure is raised, the fender body will automatically fall off the mould.

4.Conclusion

Through the production verification, the fender contour structure is simple, mold design and manufacturing is also very concise, in addition, its size and appearance requirements, mechanical properties are in line with the design requirements. This product has been used in the drilling platform for 3 years, has been praised by the users, but also achieved good economic benefits.

Inquiry for Our Product

Zaoqiang Dacheng Rubber Co., Ltd.

E-mail

info@boatfenders.org

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.